SUPPLY CHAIN TRANSFORMATION CASE STUDY

Comprehensive Product Family Profitability Analysis

Illustrating Maximizing Profit of Supply Chain Management

- Star and dog products

- Inventory management

- Freight challenges

SUPPLY CHAIN Management RECONFIGURATION

Case Overview

- Our client is a leading player in the industry, leveraging their extensive resources and expertise to deliver top-notch products and services to customers worldwide.

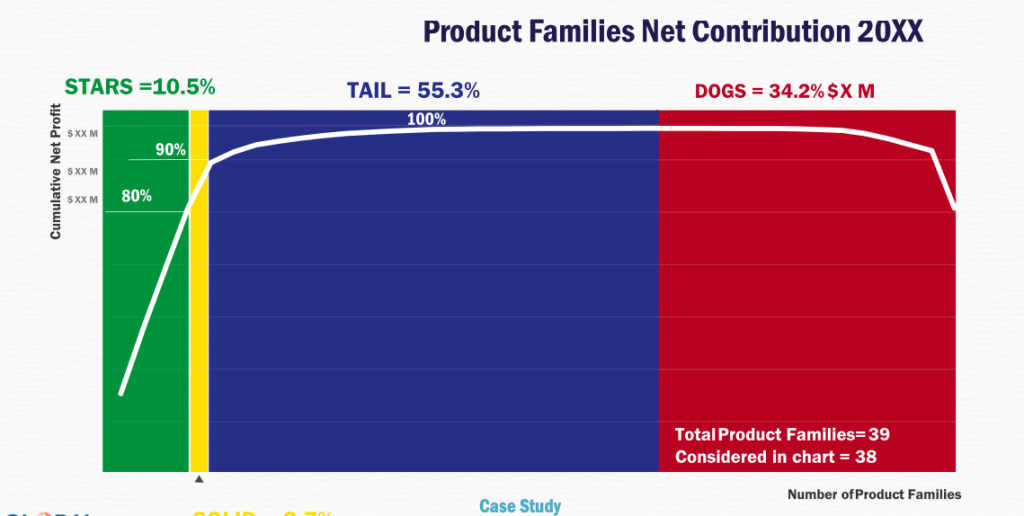

- With a diverse product family that spans 39 product family, our client offers a comprehensive suite of products to meet the ever-evolving needs of our customers.

- In addition to our client’s domestic operations, they also have a strong international presence.

Scope for this project

- This project will cover the evaluation of current processes, identification of areas for improvement, and implementation of cost-saving measures.

- The focus will be on Star and Dog products, streamlining inventory, and negotiating better rates for freight.

Methodology

- The project team will use a combination of market research, data analysis, and internal process evaluations to identify areas for improvement.

- They will also engage with suppliers, stakeholders, and customers to gather feedback and implement changes.

Setting Clear Project Objectives

- Product Family Profitability Analysis: Perform a profitability analysis to identify growth opportunities and optimize product mix.

- Streamline Inventory and Freight: Streamline inventory and freight for improved efficiency, cost reduction, and customer satisfaction.

- Star, Solid, Tail and Dog Products: Identify “Star,” “Solid,” “Tail,” and “Dog” products for optimized resource allocation and product portfolio management.

Staying Ahead of the Game:

Understanding the Latest Trends in Companies

BUFFETTED BY STRONG FORCES ON ALL SIDES

- Sophisticated product categorization and analysis

- Optimize resource allocation and increase efficiency

- Demand forecasting

- Just-in-time delivery

- High risk and high reward situation

Companies focusing on identifying the potential of their most profitable products

Understanding the Latest Trends in Companies

- The trend in the industry is towards more sophisticated product categorization and analysis, with companies focusing their efforts on identifying and maximizing the potential of their most profitable products.

- This trend is driven by the need to optimize resource allocation and increase efficiency in a competitive business environment.

- Inventory management is becoming increasingly important as companies seek to streamline their operations and reduce costs.

- Freight planning is becoming more strategic as companies seek to optimize their supply chains and reduce costs.

- Advanced inventory planning techniques, such as demand forecasting and just-in-time delivery, are becoming more prevalent in order to improve efficiency and reduce waste.

Adapting to the Market: Staying Ahead of Customer Trends

- Consumers are increasingly seeking high-quality, well-designed products that offer value for money.

- Products that are seen as “Stars” are in high demand, while those seen as “Tail” or “Dog” products may be less popular.

- Consumers expect to have access to a wide range of products and to be able to purchase items quickly and easily.

- Consumers demand fast, low-cost shipping. Companies improve freight operations to meet demand and improve customer experience.

Uncovering Insights: An Initial Assessment of Your Client's Needs

- An initial review of the client’s inventory levels may reveal inefficiencies or imbalances in their supply chain that could be contributing to higher costs or reduced margins.

- An analysis of the client’s freight costs may show that they are paying higher prices than the market average, which could be impacting their bottom line.

- An analysis of the client’s product portfolio may reveal that they are carrying too many “Dog” products, which are not contributing to their bottom line

The Effects of Not Implementing Cost-Reducing Strategies

- Failing to optimize freight and inventory operations can result in lower sales and profitability for "Star" products, while "Dog" products may continue to consume valuable resources and negatively impact the bottom line.

- An unoptimized supply chain can lead to an imbalance in the product mix, with some product families contributing more to the bottom line than others.

- This can result in reduced overall profitability and a less effective use of resources.

- It's in the best interest of our client to continuously strive to reduce costs and improve operations, in order to remain competitive and meet the changing needs of customers.

The Importance of Data Analysis

- Data analysis helps companies to accurately track inventory levels, identify trends, and make informed decisions about when to order new products and how much to order

- Data analysis provides valuable insights into shipping costs and can help companies to identify opportunities for reducing costs, such as negotiating better rates with carriers, optimizing shipping routes, and reducing shipping times.

- Data analysis provides valuable insights into the profitability of each product family.

Data Analysis:

Insights into product family profitability

- Inventory Management-to minimize the risk of obsolescence

- Freight Costs-negotiating better rates with carriers

- Product Family Profitability Analysis-determine the profitability of each product family

What supply chain projects will adequately fix the root causes Forever?

Maximizing Potential: The Key Actions for improvement

- Inventory Management- Companies can improve their inventory management by regularly analyzing data to track inventory levels, identify trends, and make informed decisions about when to order new products and how much to order. This can help to minimize stock shortages and reduce the risk of excess inventory.

- Freight Costs: Companies can reduce freight costs by analyzing shipping data to identify opportunities for reducing costs, such as negotiating better rates with carriers, optimizing shipping routes, and reducing shipping times.

- Product Family Profitability Analysis: Companies can improve their overall profitability by regularly analyzing data to understand the profitability of each product family. Based on this information, companies can make informed decisions about which product families to invest in, which to discontinue, and which to grow.

- Customer Data Analysis: Companies can improve their customer experience by regularly analyzing customer data to understand their preferences, buying habits, and feedback. This can help companies to make informed decisions about which products to offer, how to price them, and how to improve the customer experience.

- Technology Adoption: Companies can improve their operations by adopting new technologies such as artificial intelligence, machine learning, and automation. These technologies can help companies to streamline operations, reduce costs, and enhance customer satisfaction

Unfortunately, most of the Current efforts towards cost saving were ineffective and ineffectual.

Our client was not the only one experiencing a profit crunch. the Entire industry was going through a big upheavel.

SCENARIO 1

With pilot testing in this configuration our client was able to save 33% in inventory and 25% in freight. Raising the profits by X% and reducing the effect of dog products by Y%.

SCENARIO 2

–With pilot testing in this configuration our client was able to save 40% in inventory and 40% in freight. Raising the profits by A% and reducing the effect of dog products by B%

SCENARIO 3

With pilot testing in this configuration our client was able to save 50% in inventory and 50% in freight. Raising the profits by C% and reducing the effect of dog products by D%.

A Timeless Approach to Data Analysis for Improved Cost of Service

- The process of conducting the preliminary analysis took 4week, followed by 28 weeks of additional analysis aimed at optimizing shipping costs.

- An additional 2 Months were required to present the findings , conduction pilot test and to gain approval from the board.

Our results:

Uncovering the Benefits of product family profitability on the business

- Improved understanding of consumer behavior and preferences, allowing for better alignment of product offerings with market demand.

- Simplification of the supply chain, reducing waste and increasing operational efficiency.

- Optimization of inventory levels, reducing excess stock and freeing up valuable storage space.

- Reduction in freight costs, resulting in increased profitability and improved customer satisfaction.

- Cutting of bottom-end losses by focusing resources on the most profitable product families and phasing out under-performing products.

Data Collection: Timeframe

- Accurate forecasting and demand planning was achieved by collecting B2B, and stock transfer data for a period of 60 months

- For more efficient data analysis and machine learning, the collected data was cleaned and organized.

Project conclusions

- Trends are driving the need for companies to be more strategic and innovative in their approach to product management, inventory planning, and freight operations

- Neglecting to optimize freight and inventory operations can have a significant impact on a company’s bottom line, potentially leading to lower sales and profitability for key products, as well as an imbalance in the product mix.

- Data analysis can play a critical role in improving inventory management, reducing freight costs, and optimizing the profitability of product families.

Data analysis can play a critical role in improving inventory management, reducing freight costs, and optimizing the profitability of product families.