SUPPLY CHAIN 3.0

In the last entry, I have talked about the first two pillars underpinning Supply Chain 3.0. So, what are the other three key cornerstones? Transaction Optimisation Profitability (TOP) measures the ability to simultaneously minimize the costs, and maximize the revenues on each transaction that a company enters into. Consider this – there are companies today that change their pricing dynamically more than 10 million times a month.

Why? To able to maximize their revenue based on pricing power they gain out of big data analytics. On the other hand these, and other, companies are constantly looking at ways to shave off fractions of pennies from each of their cost creators.

Know More About SUPPLY CHAIN 3.0

There is a full discussion (chapter 10) of this in the book “The 5-STAR Business Network“ and, if time allows, I might even write a whole book on this topic alone at some time in future

This is after all the hallmark of supply chain 3.0. Advanced Product Phasing (APP) measures the ability of a company to create a pipeline of products that lead it to sustain its market leadership.

How many one-hit wonders such as blackberry have you seen? Is Apple, after Steve Jobs, losing its Advanced Product Phasing capability?

How can a company balance its drive to milk the current products with its drive to create new products?

These are some of the interesting questions that you can explore in more detail once you start thinking in the realms of Advanced Product Phasing (APP).

Suffice it to say here that it is one of the key cornerstones of supply chain 3.0.

Finally, Results-focused, Modularised Outsourcing (ROM) is so important to supply chain 3.0 that I have already written a follow-up book to talk about this concept.

If you read nothing else on this topic, just the foreword by an illustrious strategist and CEO (Philippe Etienne, Managing Director & CEO, Innovia Security Pty Ltd) is worth reading. Here is an excerpt:

Today, when I mentor C-Level executives on how to make the jump to the role of CEO, many struggle to move their thinking from functional excellence to cross-functional leadership.

In many people’s minds, even the characterization of a corporate leader seems to be shrouded in mystery– ranging from a motivational speaker to a whip wielding slave-driver.

One thing I have noticed all good corporate leaders have in common is their ability to pick and extract the power from uncommon teams – teams of internal experts and external service providers who can aggregate, work well together under pressure, and create the magic called success.

That is where it becomes critical to outsource well. No doubt, today every company outsources at least some part of its activities.

With outsourcing being so ubiquitous now, and of such strategic importance that some of the best known businessmen on earth spend a significant amount of their time getting it right – it is a wonder why many people are not taking it just as seriously as these business stalwarts are.

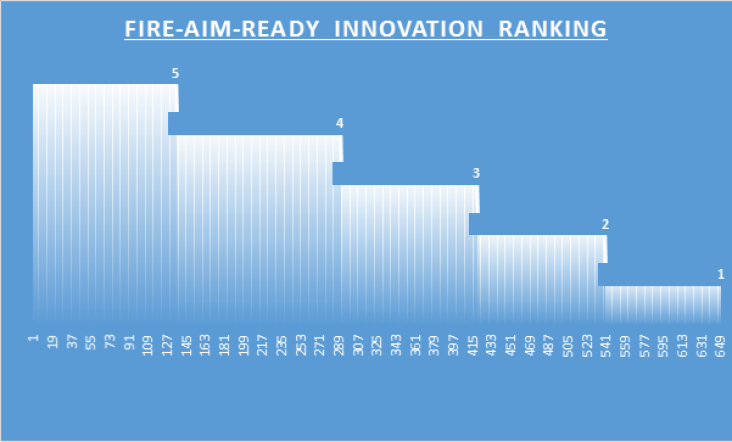

So, what does the data say about how real is supply chain 3.0. We already noted that 62 companies meet the cut-off of 20 points out of 25. Let us now look at the rest of the database and try to answer the question that is on everyone’s mind.

SUPPLY CHAIN 3.0 Innovation Ranking

Figure – Ratio of Market Value to Profit in 2012 for 932 companies

As shown in the figure above, only 5% of the companies in our dataset of 1200 global leaders meet the criteria for supply chain 3.0 and another 30% meet the criteria for supply chain 2.0.

Rest of the companies (nearly 65% or 780 companies out of 1200) are somewhere between supply chain 0.0 and supply chain 1.0.

You can see the list in the appendix of the book “The 5-STAR Business Network“.

Just be mindful that no company is uniformly excellent, or sub-par in all its divisions and geographical areas, although the results above show them as such.

From our work in various divisions of the same corporation we know that pockets of excellence do exist in many sub-par companies and vice-versa.

The History of SUPPLY CHAIN 3.0

In fact, one of the biggest sources of supply chain friction is exactly this – the variability (sigma) of supply chain performance between various parts of the same business network.

But, that is a topic for another blog. While we have seen from the data above that supply chain 3.0 is real, here and now.

In future blog posts we will establish the internal workings of supply chain 3.0 and show the transition points from supply chain 2.0 to supply chain 3.0, from supply chain 1.0 to supply chain 2.0,

and further on from supply chain 0.0 to supply chain 1.0. Why was it necessary to ‘invent’ supply chain management in the first place.

There already existed the discipline of logistics, materials management, inventory management etc. A company’s position on this spectrum will ultimately dictate its performance.

Just as is the case in professional golf or tennis – winners in the game of supply chains or business networks take away bulk of the prize pool.

The 5-STAR Business Network: And The CEOs Who Are Building The Next Generation Of Super Corporations With It

SUPPLY CHAIN 3.0 In the last entry, I have talked about the first two pillars underpinning Supply Chain 3.0. So, what are the other three key cornerstones? Transaction Optimisation Profitability (TOP) measures the ability to simultaneously minimize the costs, and maximize the revenues on each transaction that a company enters into. Consider this – there are companies today that

URL: https://www.amazon.com/The-5-STAR-Business-Network-Corporations/dp/061579419X

Author: Vivek Sood

5